I thought I would start a discussion about whether to use PP (polypropylene) or

PU (polyurethane) material as an exterior mod.

I have searched the forum and there isn't anything on it.

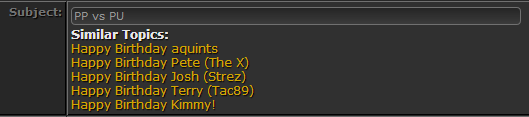

Infact when creating this post, searching PP vs PU results in this:

I don't know why...

Anyways, I've always asked myself should I use PP or PU for my body kit?

It's such a big question because body kit retailers are selling kits in either PP or PU.

For those who are curious like myself, here's an insight of PP and PU.

I found that people from other forums were getting confused with themselves.

But the below information is what I've collected from them.

After using a bit of logic, both characteristics of PP and PU

have been properly allocated to their right name.

Again please correct me if I'm wrong.

Polypropylene (PP) - Is like plastic. It can crack and scratch and unfortunately won't bend.

We had a member in Mount Gambier who had ABS plastic (similar to PP) and reversed into a pole

and had a massive sharp hole/crack in his rear bumper. But PP is good for side skirts and Spoilers

But not as bumpers.

Polyurethane (PU) - Has high tensile strength, Impact resistant, high compressive strength,

and resists stress cracking while retaining stiffness and flex.

So basically this means, if you run into something, it can bend, but obviously, if bent too much, it'll crack.

Ideally it's better to get PU. But if you're confident about not getting into accidents, PP should be okay.

But both are definitely legal.

According to the clubcj, Fibreglass is illegal on the road. DO NOT get the below terminologies you see

over the internet:

Carbon Fibreglass

Fibreglass

FRP

FB

Dry Carbon

etc. Apparently, it can be quite dangerous and sharp in accidents where as PP and PU can take a bend effect.

If you guys have anything to add to this, start posting!